UniLinc™- Your On-Premises Laundry Partner

UniLinc is a complete OPL control system that allows you to gather machine performance and maintenance data. Designed with both washer-extractors and tumblers in mind, our advanced controls and reports provide ease of use across all your machines to help you achieve maximum efficiency. With UniLinc, you can instantly access machine service history logs, receive error notifications, view performance reports and perform many other time- and money-saving tasks. And with wireless networking, you can do it all remotely, saving even more time and money. UniLinc also unites UniMac® technologies like 400 G-Force extraction, OPTidry™ Over-dry Prevention and OPTispray™ Rinsing Technology to offer the industry’s lowest cost of ownership.

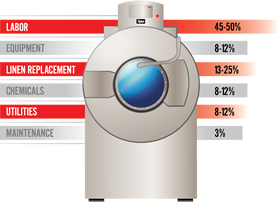

The Measure of OPL Success

Save Water and Energy

- OPTispray Rinsing Technology provides highly effective rinsing that uses less water and decreases overall utility costs

- Nine ECO cycles available to minimize water and energy consumption

- Industry-leading 400 G-Force extraction decreases drying times, thus reducing gas and labor costs

- Automatic water leak detection and slow drain detection identify errors, like a slowly leaking fill valve, before they become bigger issues—helping you save water and sewage costs

- OPTidry prevents over-drying and saves utility, labor and linen replacement costs

- Industry-leading fast cycle times deliver low electricity costs

Increase Throughput

- OPTispray reduces cycle time by 12 percent

- Slow drain detection monitors drain time to catch issues early and reduce maintenance expenses

- Automatic water leak detection monitors and alerts you to leaks, helping you address errors promptly

- Advanced start feature finishes a wash load before employees arrive to increase productivity

Wirelessly Monitor Your Laundry

- Manage your entire laundry operation off-site from any Internet-connected computer

- Wireless networking for remote monitoring of multiple machines and locations for optimal efficiency

- Service-related audit data helps manage equipment costs and ensure longevity

- Automatic warning emails alert you in real time to help avoid OPL maintenance costs

- Diagnostics and troubleshooting help you quickly self-diagnose problems

- Automatic OPL maintenance reminders reduce downtime with timely servicing

- Access to data reports for programming and troubleshooting

- Records start time, stop time and idle time between cycles for easy labor monitoring

- Records when OPL operators cut cycles short, helping you monitor quality

- Records when a machine is out of balance, an indicator of poor loading practices that cause wasted labor, chemical and utility costs

- Records highest water temperature reached for each cycle for quality control

Gain Flexibility and Control

- 41 customizable cycles make it easy to choose the right wash cycles based on linen type

- Programmable water levels allow you to offer the most economical cycles to control water usage

- Temperature-controlled fill, thermal cool-down and soak capability for optimal fabric care

- Eight simple chemical connections with easy programming

- Wet clean capability meets special washing needs

Easy to Use

- User-friendly graphic display simplifies training and OPL operations for fewer errors

- UniLinc software offers easy programming of multiple machines at once

- Six customizable languages for multilingual operation and easier training

- Same control for both OPL washers and OPL tumblers streamlines operator use and training

- One-touch operation allows you to simply select a cycle and push start